PROCESS

Nuna Cotton produces a wide range of sustainable clothing, from basics to elaborate fashion, with innovative fabrics and special finishes. It consists of the following stages:

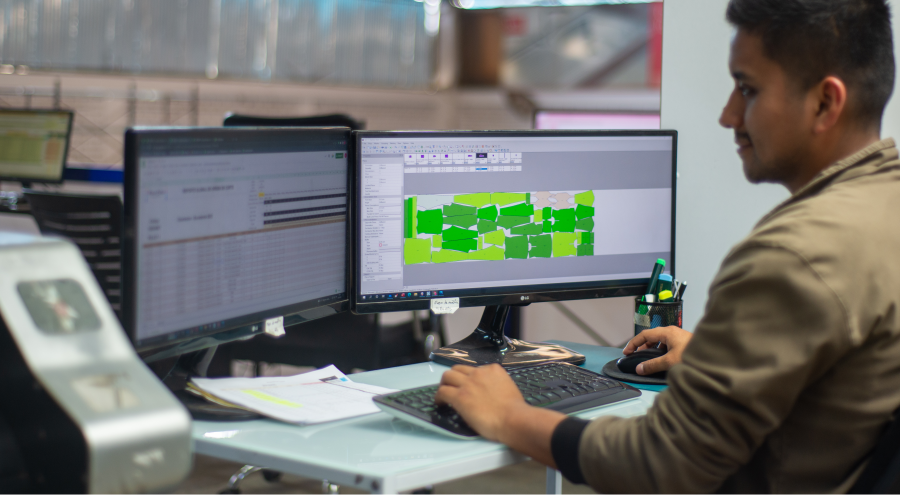

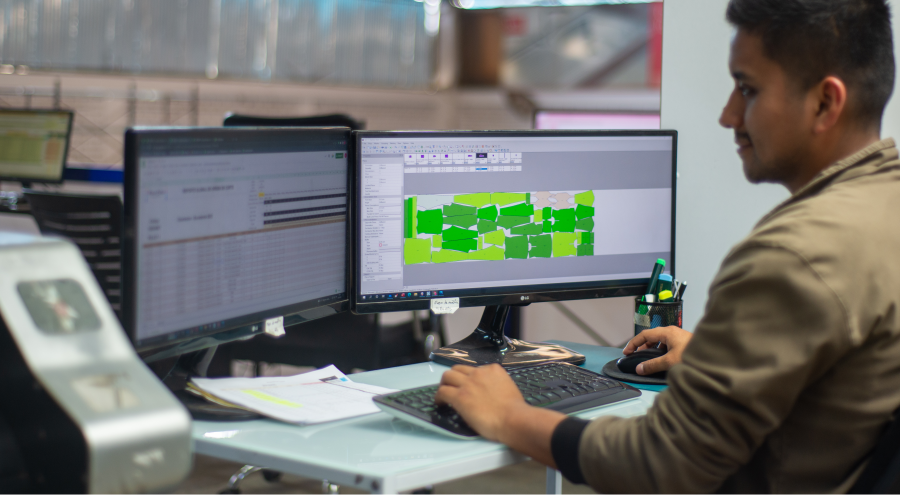

Simulation of Production Programs

Nuestro sistema de producción identifica “cuellos de botella” y toma acciones correctivas para cumplir con los compromisos de entrega acordados con los clientes y reducir los tiempos de entrega.

for line fabrics

|

For Garments

|

Production Lead Time

|

|---|---|

|

basic solid colors

|

4 to 6 weeks

|

|

Full Print

|

+ 1 weeks

|

|

handmade embroideries

|

+ 1 to 2 weeks

|

|

handmade smock

|

+ 1 to 2 weeks

|

|

Crochet

|

+ 1 to 2 weeks

|

|

“Quick response” or reorders

|

4 to 5 weeks

|

|

Development of new colors of fabrics or new fabrics

|

4 to 6 weeks

|

Development of new fabric colors or new fabrics

|

Criterion

|

Production Minimums

|

|---|---|

|

By Color

|

800 to 1000 garments

|

Development of new fabric colors or new fabrics

|

Criterion

|

Production Minimums

|

|---|---|

|

By Size

|

12 units

|

|

By Color

|

108 to 130 garments

|

|

By Style

|

130 to 260 garments

|

|

By Color

|

260 to 390 garments

|

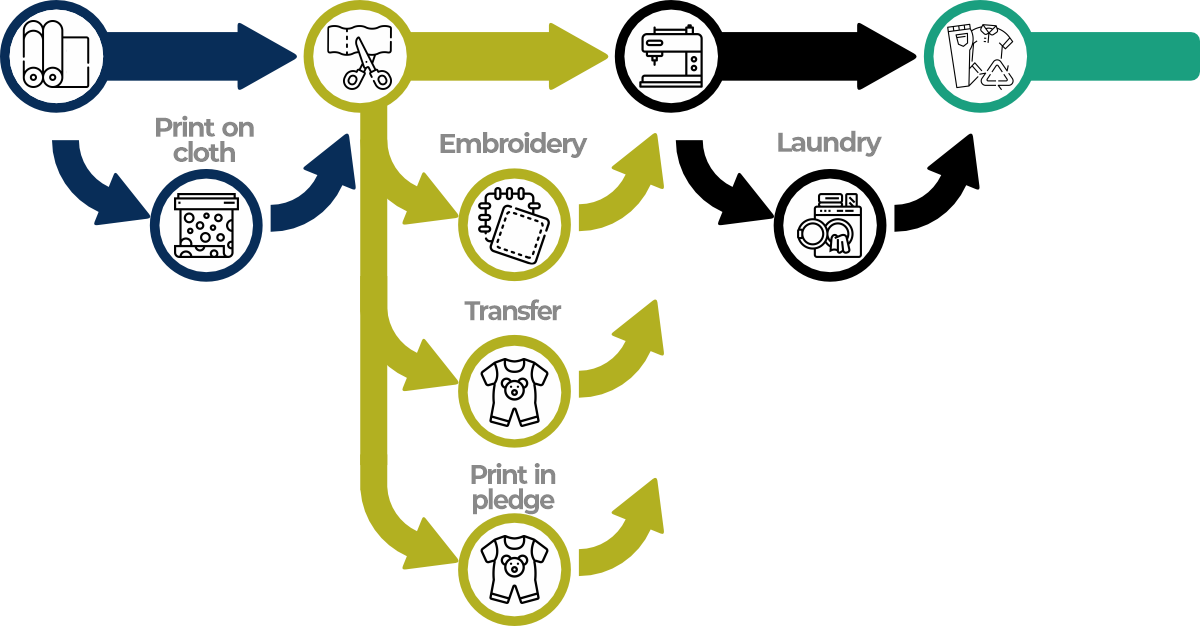

Production Route

We control our production flow to guarantee efficiency and quality throughout the production process.

Raw material

Nuna Cotton in production works exclusively with suppliers that have quality certifications and are committed to sustainability. This guarantees that our products are manufactured with the highest standards and respecting the environment. We value excellence and responsibility at every stage of our supply chain.

Fabric print

In recent years, we have made significant investments and now have two state-of-the-art digital printers. These printers allow us to print directly on fabric, which allows us to save up to 70% in water consumption per garment; also with serigraphic machines that work with water-based dyes without PVC.

Court

Our cutting area has Audaces NeoCut Bravo machinery in order to ensure the stability of the garment and minimize fabric waste as much as possible. We have a capacity of 500,000 garments per month.

Embroidery

In our commitment to provide quality garments and promote local development, we are proud to highlight that we have implemented a project in collaboration with the local community, where we develop the artisan talent of our region and manage to obtain the best handmade embroidery in the world.Garment print

In our commitment to sustainability, we have acquired direct-to-garment digital printing technology in our production process. With this innovative technique we have managed to reduce water consumption per garment by up to 70% compared to traditional printing methods.Sewing

Our sewing team is trained to perform a wide range of techniques and finishes.

From bartacking and blindstitching to button gluing, single-needle topstitching, double-needle topstitching, flatlock sewing, elastic fastening, buttonholes, stippling, collar and hem assembly, among others.

We have a capacity to produce 500,000 garments in 14 minutes STD time.

Our sewing team is trained to perform a wide range of techniques and finishes.

From bartacking and blindstitching to button gluing, single-needle topstitching, double-needle topstitching, flatlock sewing, elastic fastening, buttonholes, stippling, collar and hem assembly, among others.

We have a capacity to produce 500,000 garments in 14 minutes STD time.

Washed

To carry out this process, we have the latest technology in washing machines, which allows us to obtain exceptional results with minimal water consumption. By using cutting-edge technology, we ensure that our garments are treated responsibly, obtaining a high-quality finish without compromising our natural resources.finishes

In our finishing department, we follow a process line that includes snap gluing, ironing, folding and bagging. ensure a quality finish. This is achieved through the use of 4 automatic broaching machines that regulate the pressure precisely and efficiently.

Our commitment is to offer excellent products to our customers.

Dispatch

In our dispatch process, we carry out a final inspection of the garments to ensure that they meet the specified standards of our clients.

Each garment is carefully weighed and packed in appropriate boxes before being shipped to the customer. Customer satisfaction is our priority, and we strive to offer an efficient and reliable dispatch service.

Purchase of Fabric

In our commitment to sustainability, we continually strive to be more environmentally friendly. To achieve this, we constantly search for the best suppliers whose chemical products are the most sustainable. Additionally, we are proud to say that our suppliers recycle 50% of the water used in the entire dyeing process. Our goal is to responsibly acquire the necessary resources to minimize our impact on the natural environment. Together, we work for a more sustainable future.

Fabric print

In our quest to be more sustainable, we have focused on improving our fabric printing process. In recent years, we have made significant investments and now have two state-of-the-art digital printers.

Court

In our production, we have efficient machines that allow us to minimize fabric waste. We use advanced technologies to optimize resources and promote sustainable production. Our goal is to reduce our environmental footprint and contribute to a more conscious future.

Embroidery

We carry out transfers using the most sustainable chemicals, guaranteeing that they are washable and durable, without compromising the quality of our products. We strive to deliver excellence in every aspect of our work, delivering high-quality results with every transfer we make.

Sewing

In our sewing department, we have a wide variety of sewing machines from well-known brands. Our sewing team is trained to perform a wide range of techniques and finishes. From bartacking and blindstitching to button gluing, single-needle topstitching, double-needle topstitching, flatlock sewing, elastic fastening, buttonholes, overstitching, collar and hem assembly, among others. We are committed to quality and precision in each of our garments, and we have the necessary tools to guarantee impeccable finishes. Our sewing team is skilled at their craft and strives to deliver high-quality products.

Washed

At Nuna Cotton, we are proud to offer the garment wash service, a garment finishing process that adds a special touch to our products. To carry out this process, we have the latest technology in washing machines, which allows us to obtain exceptional results with minimal water consumption. We are committed to sustainability and constantly seek to reduce our environmental impact. By using cutting-edge technology, we ensure that our garments are treated responsibly, obtaining a high-quality finish without compromising our natural resources. We work hard to combine excellence in our products with care for the environment.

Quality

In our commitment to sustainability, we have implemented direct-to-garment digital printing technology in our production process. This innovative technique allows us to achieve high-quality prints without the need to use large amounts of water. In fact, thanks to this technology, we have

finishes

In our commitment to sustainability, we have implemented direct-to-garment digital printing technology in our production process. This innovative technique allows us to achieve high-quality prints without the need to use large amounts of water. In fact, thanks to this technology, we have managed to reduce water consumption per garment by up to 70% compared to traditional printing methods. We are proud to contribute to caring for the environment by reducing our water impact and continuing to offer excellent products. Together, we move towards a more sustainable future.

Dispatch

In our commitment to sustainability, we have implemented direct-to-garment digital printing technology in our production process. This innovative technique allows us to achieve high-quality prints without the need to use large amounts of water. In fact, thanks to this technology, we have managed to reduce water consumption per garment by up to 70% compared to traditional printing methods. We are proud to contribute to caring for the environment by reducing our water impact and continuing to offer excellent products. Together, we move towards a more sustainable future.

Our Certifications